At Product Assurance Services, Inc. (PASI), we pride ourselves in being a “best-in-class” testing and evaluation facility, with evidence from our many satisfied customers. If you have ever been in an independent laboratory, you will be pleasantly surprised at our surroundings. Our facility is bright, clean, and well organized.

We Specialize In:

- Customer Service: On-site metallurgical support, supplier-customer interaction

- Materials Testing & Control: Powder characterization, green and sintered testing

- Product Quotation: Material & process selection

- Product Evaluation: Verification of metallurgical conformance of in-process or finished parts

- Raw Material Supplier Development: Heat treaters, platers, grinding, machining

- Failure Analysis: Powdered metal & wrought products: shafts, fasteners, gears, etc.

Our Testing Includes:

Our Testing Includes:

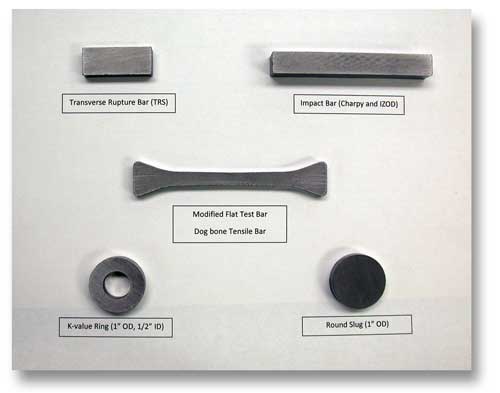

Metallography, Hardness, Micro-hardness, Density, Tensile, Crush, Experimental Blending, Molding for P/M (TRS Bars, K-Value Rings, 1” Round Slugs, Impact Bars, Tensile Bars), etc.

We also perform Cleanliness Testing to a wide variety of procedures. Cleanliness testing is becoming a requirement for many industries and PASI is a clean, capable laboratory to assist in your needs.

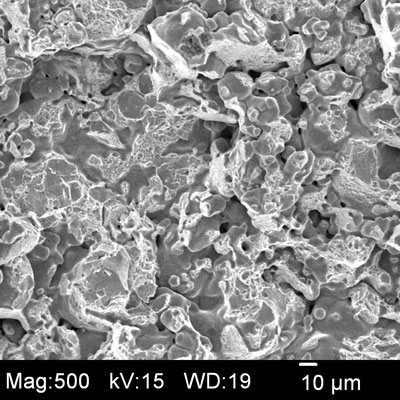

Scanning Electron Microscope

The scanning electron microscope (SEM) is a significant part of our laboratory services. It’s an important research tool in many areas of science and technology because its magnification (30X to over 150,000X), great depth-of-field, and resolution, from a few nano-meters to a few Angstroms, are unequaled by other forms of microscopy. The SEM is relied upon for failure analysis (fractography), particle examination and characterization, metallography, etc.